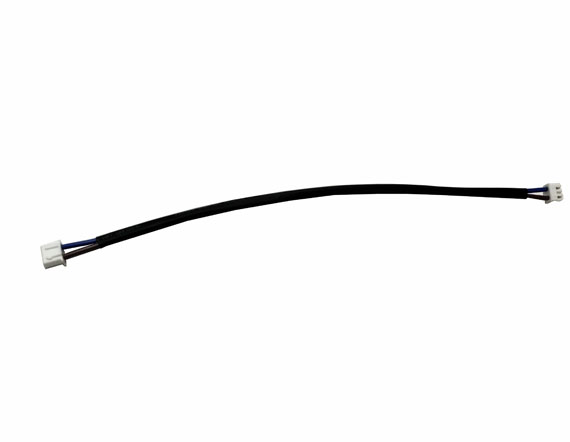

Insulated terminal wires are crucial components in any safe electrical system. Designed to protect users and equipment, these wires feature insulation that prevents current leakage, reduces heat buildup, and protects against external hazards. At XPB, a leading manufacturer in the field, we prioritize quality and durability to deliver high-performing terminal wires for a wide range of applications. In this article, we’ll explore the essential features of insulated terminal wires and highlight why they are ideal for safe, reliable electrical connections.

Key Features of XPB Insulated Terminal Wires

1.High-Quality Insulation Materials

The choice of insulation material directly affects safety, durability, and heat resistance. XPB insulated terminal wires use advanced materials such as PVC or silicone, designed to endure high temperatures and withstand wear over time. This insulation minimizes the risk of electric shock, making it a safer choice for both commercial and residential installations.

2.Excellent Electrical Conductivity

Insulated terminal wires from XPB are engineered with high-conductivity copper or aluminum cores, which facilitate efficient current flow while maintaining safe temperatures. This optimal conductivity helps to minimize energy loss, ensuring both safety and cost efficiency in various applications.

3.Resistance to Environmental Hazards

XPB terminal wires are built to withstand moisture, corrosion, and other environmental hazards that could compromise the integrity of the wire. This makes them an ideal choice for outdoor or industrial applications where exposure to harsh conditions is a factor. The insulation protects against weathering, which extends the wire's service life.

4.Enhanced Safety Ratings

XPB’s insulated terminal wires comply with international safety standards, offering protection against electrical hazards. By choosing certified and tested terminal wires, users can rest assured that their installations meet stringent safety regulations and offer long-lasting reliability.

Common Applications of Insulated Terminal Wires

1.Automotive Wiring Systems

Automotive applications require wires that can withstand high temperatures and vibrations. XPB insulated terminal wires are suitable for use in vehicles as they provide consistent performance and safety.

2.Home Appliances

Safety is essential in home appliances, especially those operating at high temperatures or in wet environments. XPB insulated terminal wires prevent electrical hazards, making them ideal for kitchen appliances, air conditioners, and heaters.

3.Industrial Equipment

Industrial machinery and equipment demand high-quality terminal wires that resist environmental stressors. XPB’s wires offer durability and safety, making them reliable choices for heavy-duty applications.

4.Renewable Energy Systems

Renewable energy systems, such as solar panels, rely on high-quality wiring that can withstand temperature changes and moisture. XPB’s insulated terminal wires ensure safe connections in both residential and commercial solar installations.

Why Choose XPB for Insulated Terminal Wires?

As an established terminal wire manufacturer, XPB offers quality, durability, and innovative solutions tailored to meet diverse needs. Our team is dedicated to providing custom solutions for clients, from bulk orders to specialized wiring requirements. By choosing XPB, you gain access to top-tier products designed with safety, efficiency, and longevity in mind.

For more information about XPB insulated terminal wires, visit our website here.