Electronic wiring harnesses and terminal connectors are critical components in modern electronic devices. They play an essential role in connecting various parts of the circuit to facilitate the smooth transmission of electrical signals and currents. Selecting the right electronic wiring harness and terminal connector is crucial to ensure the optimal functioning of electronic equipment. In this article, Xinpengbo Electronic Technology outlines the key criteria for choosing the appropriate wiring harnesses and connectors, assisting engineers and technicians in making well-informed decisions.

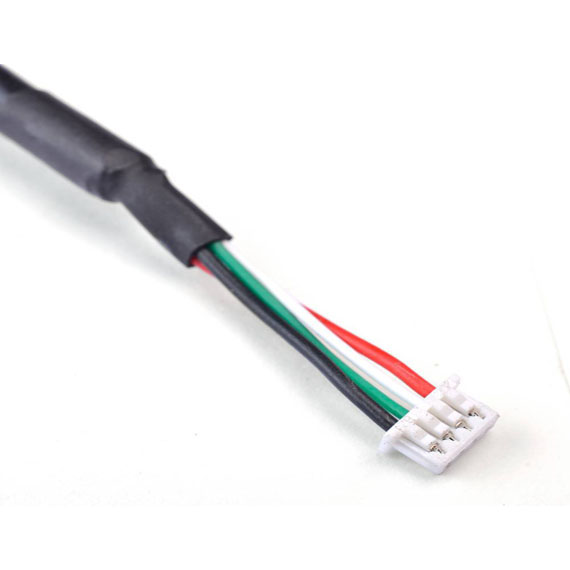

Electronic Wiring Harness

1.Preparation Before Selecting Wiring Harnesses and Terminal Connectors

Before choosing the appropriate components, it is essential to thoroughly analyze the circuit's characteristics and the equipment's working environment. This involves assessing electrical parameters like circuit voltage, current, frequency, and impedance, as well as environmental factors such as installation location, temperature, humidity, and vibration. Only after understanding these key aspects can one accurately select the correct wiring harnesses and terminal connectors.

2.Electrical Performance Considerations

Current Capacity: The connector must be able to handle the maximum current flow in the circuit. During selection, calculate the required current capacity based on the circuit load, and ensure there is a margin for potential increases in future loads.

Voltage Level: The connector's voltage rating must align with the circuit’s rated voltage. Using a connector with the wrong voltage rating can cause insulation failure, jeopardizing the circuit’s safety.

On-Resistance: Lower on-resistance in a connector minimizes energy loss and boosts circuit efficiency. Connectors with low on-resistance should be preferred to ensure optimal performance.

3.Mechanical Performance Considerations

Torque Requirements: Proper torque ensures a tight and secure connection, preventing loosening due to factors like vibration or temperature shifts. Select a connector with the appropriate torque range as specified by the manufacturer, and use professional torque tools for installation.

Mechanical Strength: A connector's durability is crucial, particularly in challenging environments. If the equipment requires features like waterproofing or dust resistance, choose a connector that offers adequate mechanical strength for the given conditions.

4.Additional Considerations

Structural Dimensions: The external size of the terminal wires is vital, especially if there are space constraints within the device. Ensure that the chosen connector fits within the spatial layout of the equipment.

Impedance Matching: For specific signals, such as radio frequency signals, impedance matching is essential for maintaining signal integrity. Choose connectors that support proper impedance matching to ensure reliable signal transmission.

Shielding Performance: In modern electronics, electromagnetic compatibility (EMC) is increasingly important. When selecting a connector, consider its shielding capabilities to protect the equipment from electromagnetic interference in complex environments.

Anti-Misinsertion: To prevent incorrect signal connections, choose connectors that feature anti-misinsertion mechanisms. Adjusting the relative positioning of the connector can also ensure the correct assembly.

Reliability: The reliability of a connector directly influences the overall performance and longevity of the device. Opt for connectors that offer proven stability and reliability.

Versatility: Whenever possible, choose versatile connectors that can serve multiple purposes. This reduces material variety, enhances cost-efficiency, and mitigates supply risks.

Conclusion

Selecting the appropriate electronic wiring harnesses and terminal connectors is a multi-faceted process that requires careful consideration of both electrical and mechanical performance. By fully understanding the equipment’s circuit characteristics and environmental demands, engineers and technicians can make informed decisions that ensure the efficiency, stability, and safety of electronic devices. A thoughtful selection process not only boosts equipment performance but also extends its operational lifespan.

For more details on high-quality connectors, you can explore the product offerings at Xinpengbo Electronics.