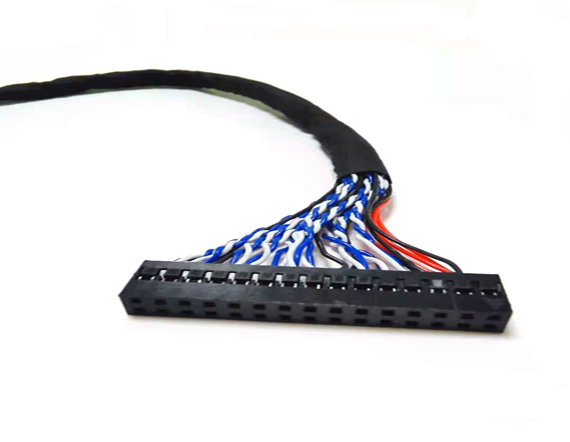

Terminal wires are an essential component of any electrical system, connecting different devices and enabling smooth transmission of electrical signals. However, like any other electrical component, terminal wires can develop problems over time. In this guide, we will explore some of the common issues encountered with terminal wires and provide effective troubleshooting techniques to resolve them.

One of the most prevalent problems with terminal wires is loose connections. These can occur due to improper installation, wear and tear, or vibrations. Loose connections can result in intermittent current flow or even complete disconnection, causing equipment malfunction or failure.

To troubleshoot loose connections, follow these steps:

Corrosion is another common issue that affects terminal wires, especially in humid or corrosive environments. Corrosion can weaken the wire's conductivity and lead to voltage drops, resistance, or intermittent connections.

To troubleshoot corrosion, follow these steps:

Over time, terminal wires can experience fraying or breakage, usually caused by excessive bending, pulling, or poor insulation. This problem can lead to improper electrical connections and pose safety hazards.

To troubleshoot wire fraying or breakage, follow these steps:

Using an incorrect wire gauge for a specific application is a common mistake. If the wire gauge is too thin, it can cause voltage drops, overheating, and potential equipment damage. On the other hand, using a wire gauge that is too thick can add unnecessary cost and bulk to the installation.

To troubleshoot improper wire gauge, follow these steps:

Overloading occurs when the current flowing through the wire exceeds its rated capacity. This can lead to overheating, insulation damage, and even electrical fires.

To troubleshoot overloading issues, follow these steps:

In conclusion, terminal wires are prone to various problems such as loose connections, corrosion, wire fraying, improper wire gauge, and overloading. By following the troubleshooting techniques outlined in this guide, you can identify and resolve these issues effectively, ensuring the optimal performance and safety of your electrical system. Regular inspection, maintenance, and adherence to safety guidelines are crucial to prevent and address terminal wire problems.